Enterprise Asset Management

What is Enterprise Asset Management ?

Enterprise asset management (EAM) is a combination of software, systems and services used to maintain and control operational assets and equipment. The aim is to optimize the quality and utilization of assets throughout their lifecycle, increase productive uptime and reduce operational costs.

Importance of Enterprise asset management

- helps organizations track, assess, manage and optimize asset quality and reliability

- sustainability of equipment needed to sustain production, services and operations

- Centralized asset information – It automates critical asset management workflows and makes them accessible and auditable

- Maximize asset utilization – Historical and real-time data collected from IoT devices and analytical and diagnostic tools help extend the availability, reliability and usable life of physical assets.

- Manage aging assets and infrastructure

- Consolidate operational applications.

Example Of Asset Management

One of the biggest MNC aims to build and strengthen the client’s portfolio. The AMC manages individuals, intermediaries, and institutions. They have a global team of investment professionals to introduce well-researched investment opportunities. Their trending options include ETF investing, separately managed accounts, variable insurance portfolios, commingled pension trust funds, and sustainable investments.

Many Large organizations have a high strategy among AMCs. These organizations have come up with innovative solutions by exploring a range of different asset classes. In addition, they have added the ESG factor to their product range and have worked upon interesting investment themes like edutainment, security, and digital health.

They offer a wide range of products, including sustainable investing, thematic equity investing, convertible bonds, and emerging corporate bonds.

Key Features of Effective EAM

- Work management

Centrally manage planned and unplanned work, from initial request through completion and including the recording of actuals

- Phases of maintenance

Move from corrective maintenance, when repairs are made after a problem occurs, to preventive maintenance (using scheduled repairs) and predictive maintenance, when repairs are made because data indicates imminent failure

- Planning and scheduling

Graphically view work orders and preventive maintenance schedules on a Gantt chart. Intuitively navigate work order management to help dispatchers manage task and work dependencies.

- Supply chain management

Assets and the materials used to maintain them are part of the supply chain. Effective solutions should incorporate IoT technologies that help integrate EAM with supply chain management systems.

- Health and safety

Document and report environmental, health and safety concerns. Reduce risk by using incident analysis, corrective action traceability and process change management.

- Mobility

Take advantage of smartphone capabilities such as photos and voice-to-text to capture information and deliver tools, documentation and collaboration.

- Analytics

Use optimization models can be used to automate the planning, scheduling and work management processes based on analysis.

- Cloud system

Support SaaS, cloud-based deployment or hybrid cloud deployment to control costs, improve system flexibility and decrease dependency on IT.

Solution for asset management

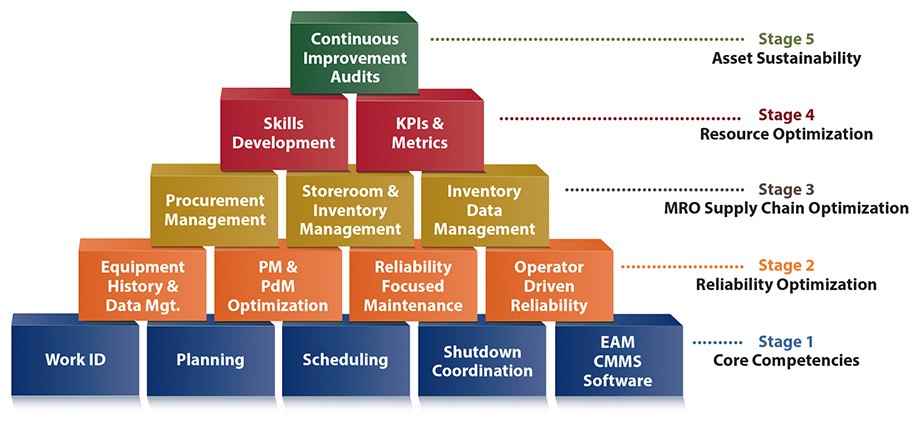

In every basket , organizations should have planning to implement these 5 stages for growth & maintenance assets.

In these Digital words, organizations must have their developed and managing software based EAM system for effective Output.

For Business consulting services,

Contact to